In the rapidly growing global tactical gear market, staying ahead of the competition requires more than just offering high-quality products. It demands innovation, precision, and quick adaptation to shifting market trends. At WINTOOLS, we use cutting-edge CNC technology to manufacture durable, customizable tactical tools that meet the exacting demands of distributors, procurement officers, and tactical gear companies worldwide. Discover how we combine precision manufacturing with tailored production to enhance your product offerings and improve your business performance in a competitive market.

The Rising Demand for Tactical Gear: A Market on the Move

The global tactical gear market is expected to grow at a CAGR of over 10% over the next five years, driven by surging demand for high-precision, durable products like tactical pens, outdoor knives, multi-functional axes, and more. As the demand for personalized solutions rises, businesses that can quickly respond to these market shifts with customizable, high-quality products will have a significant competitive edge.

For businesses in the B2B tactical gear industry, having the ability to deliver precision, speed, and customization is essential. WINTOOLS, with our advanced CNC technology, is positioned to provide these advantages, helping you meet global demands while keeping costs in check.

Why CNC Technology is a Game-Changer for Tactical Gear Manufacturers

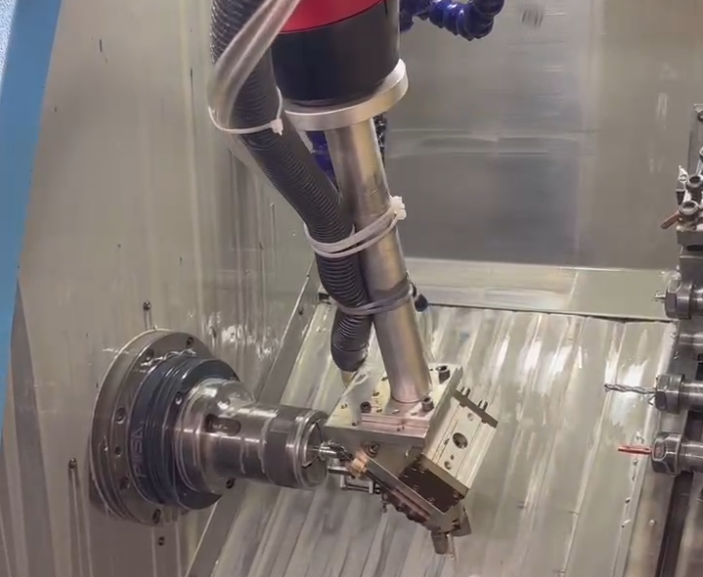

CNC (Computer Numerical Control) has revolutionized manufacturing by enabling high levels of precision and flexibility, making it an ideal solution for producing tactical tools like tactical pens, knives, and axes. At WINTOOLS, we integrate CNC processing with intelligent programming to produce top-tier tactical gear products that meet international quality standards. Here’s why CNC technology is the backbone of our success:

- Unmatched Precision: CNC machines allow us to produce parts with micrometer-level precision, ensuring that every product, from tactical pens to heavy-duty knives, meets stringent quality standards.

- Efficient Production: Whether you need small-batch customization or large-scale production, CNC technology ensures that we can quickly produce large orders without compromising on quality, reducing lead times and increasing supply chain efficiency.

- Flexible Customization: With CNC, we can handle highly personalized designs, adapting to specific needs such as engraving, material choice, and custom sizes, giving your business the flexibility it needs to stay competitive in a fast-changing market.

- Global Competitiveness: As global demand for high-quality tactical gear continues to rise, CNC technology allows us to stay on par with industry leaders, providing our clients with an edge in international markets.

Why WINTOOLS Is Your Ideal CNC Manufacturing Partner

At WINTOOLS, we do more than just manufacture products—we provide customized solutions designed to meet the unique needs of B2B clients in the tactical gear sector. Our approach is built on quality, flexibility, and a global perspective.

- Tactical Excellence: Whether you’re sourcing tactical knives for military units, multi-functional pens for outdoor enthusiasts, or specialized products for law enforcement, WINTOOLS uses CNC technology to create products that deliver superior performance in the field.

- Flexibility & Speed: In the B2B sector, being able to pivot quickly to meet changing demand is crucial. WINTOOLS’ ability to leverage CNC technology allows us to adapt quickly to your needs, offering fast turnaround times and streamlined production processes to help you meet market demands faster.

- Competitive Edge: By partnering with WINTOOLS, your business gains a key advantage in a growing global market. Our cost-effective CNC manufacturing solutions ensure that your tactical gear products are high-quality and competitively priced, helping you stay ahead of the competition.

Example: A recent client, a leading distributor of tactical gear, was able to improve their product quality by 30% and reduce production costs by 20% after switching to WINTOOLS for their CNC manufacturing needs.

Ready to Elevate Your Tactical Gear Production?

The demand for customized, high-precision products is rising, and at WINTOOLS, we’re already helping many of our clients meet these evolving needs with the power of CNC technology. From faster production timelines to tailored designs and consistent quality, our solutions will help you optimize your supply chain and stay competitive in an increasingly crowded market.

If you’re looking to improve your production efficiency, enhance product quality, and customize your tactical gear offerings, WINTOOLS is your go-to partner. Let’s connect today to discuss how our CNC manufacturing expertise can drive growth for your business and help you stay ahead of industry trends.

Contact us now to learn how WINTOOLS can help your business achieve faster production, higher precision, and cost savings with CNC technology.

Key Takeaways:

- CNC technology ensures precise, high-quality tactical gear every time.

- Flexibility in customization allows us to meet unique client needs.

- Efficient production speeds up time-to-market, giving your business a competitive advantage.

- WINTOOLS is your partner for global manufacturing, offering cost-effective solutions and customized products.